GHL Series High Speed Wet Mixing Granulator(High Shear Wet Mixing Granulator)

Principle

GHL Series High speed Wet Mixing Granulator (High shear wet mixing granulator) is equipped with a closed container with blending tools driven from above or below has long been applied by the pharmaceutical industry. The mechanical effect of the blending tools – irrespective of whether in batches or continuous operation – creates a denser granulate than the fluidized bed process.

Originally, the granulation liquid was poured into the product. Today, an improved dosed distribution using a spray nozzle is preferred in order to obtain a more even granulate.

The granules are distinguished by a compact structure and high bulk density. They have good flow characteristics and can be optimally pressed. For various applications in pharmaceuticals and related industries.

Features

1.TAYACN” considers that the machine adopts horizontal cylinder structure, its structure reasonable.

2. Air filled seal shaft for to drive. When washed , it can be changed to water.

3.Fluidized Granulation, the granule is around ball shape. Its flow ability is good.

4.Compared to traditional process, 25% of adhesive can be reduced and the drying time is short.

5.The dry mixing time is 2 minutes and the granulating time is 1-4 minutes. Compared to the traditional process , 4-5 times of efficiency is raised.

6.Dry mixing ,humid mixing and granulating are finished in the same sealed container. It is in conformity with the requirements of GMP. The whole operation has strict safe and protective measures. Jacket type might be adopted on request

7.Ensure uniform final products.

8.Granulating process is completed in a closed bowl system, dust free and complying with cGMP requirements.

9.Easy and safe operation, achieve mixing and granulating in one process.

10.HMI and PLC control system, motor speed is controlled by VFD, and all process parameters can be recorded.

11.Compressed air and water can be alternatively connected to the machine so as to ensure quick and efficient washing

We have manufactured decades specifications and 150 different machines to meet different needs. These practical experiences will be very beneficial to customers.

High process efficiency through extremely fast drying and gentle product handling. Suitable for batches of 10 to 800Liter per batch .Further batch sizes available upon request;

Application

This equipment is used for making wet granules in the solid dosage production procedure.it is also widely used in pharmaceutical, foodstuff and chemical industries.

Options

Product charging by lifting machine.

Product charging by vacuum transfer system

Jacket bowl wall design for heating or cooling

Wet mill or oscillating granulator or dry mill

Automatic binder solution spraying system

Printer

WIP system

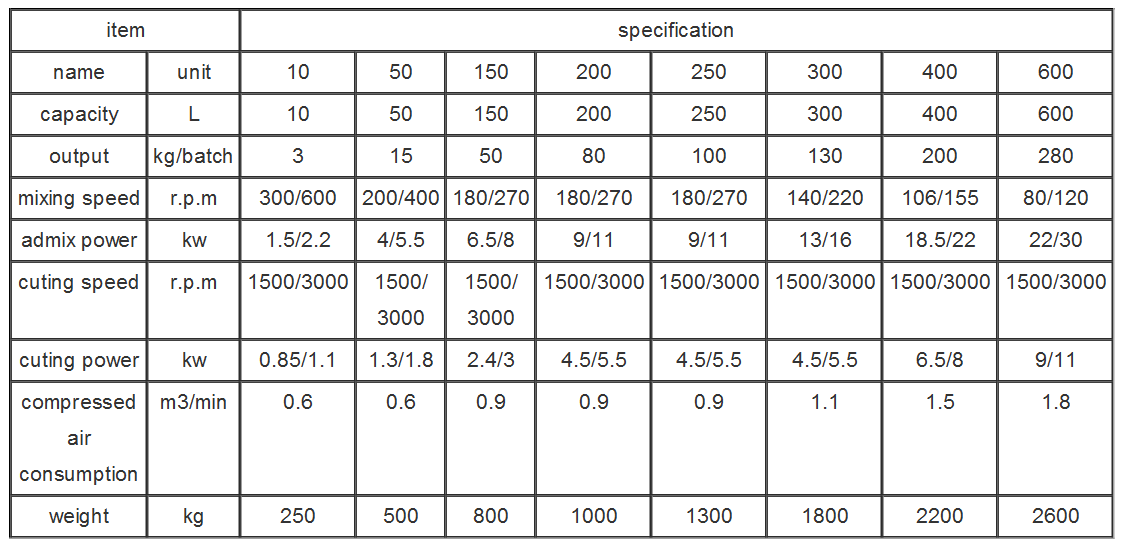

Technical Parameters