.png?x-oss-process=image/resize,w_100/quality,q_100)

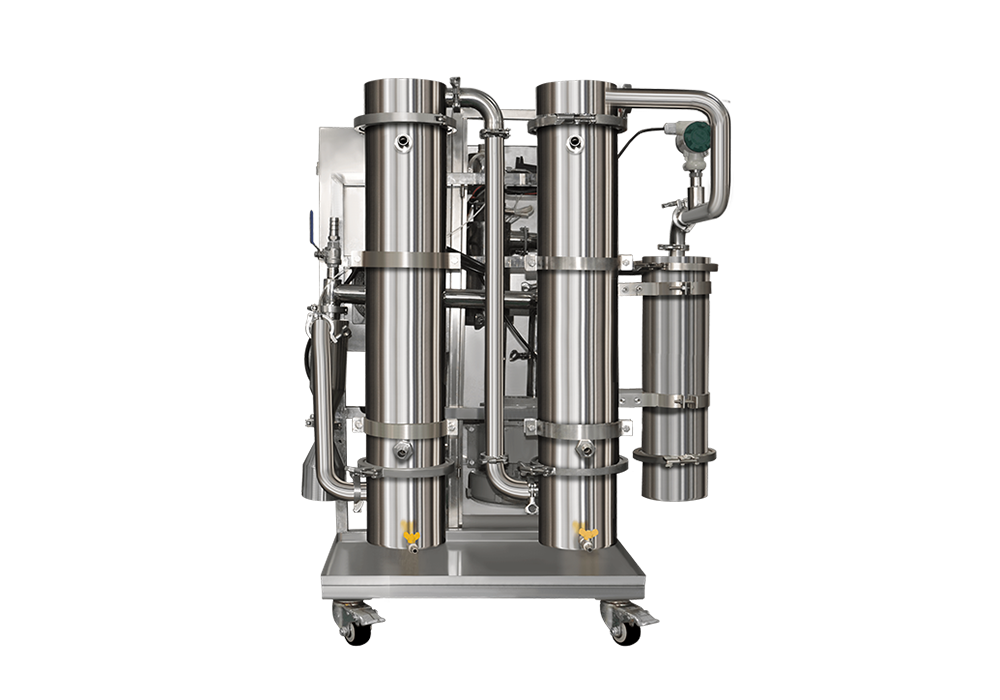

Laboratory spray dryer

HF-015 Experimental Spray Dryer (Small Spray Dryer) with a compact design, can be independently placed in a laboratory or placed on a specially designed stainless steel frame, forming an integrated unit that can operate without the need for other facilities. One-touch power on, color large LCD touch screen operation, can be operated in fully automatic or manual monitoring mode, making it convenient for operation and monitoring of the experimental process. It is currently the smallest in size, lowest in noise, and offers excellent drying effect among spray dryers.

Uses

It has been selected by over 1500 universities, institutions, and enterprises in China, including Tsinghua University, Peking University, Shanghai Jiao Tong University, Hong Kong University of Science and Technology, Nanjing University, Wuhan University, Huazhong University of Science and Technology, Chinese Academy of Sciences, Zhejiang University, Tongji University, South China University of Technology, Jinan University, Nankai University, Southeast University, China Agricultural University, General Electric, and others.

Product Application

Food, pharmaceuticals, dairy products, egg yolk, soy sauce, coffee, starch, protein, hormones, serum, antibiotics, enzymes, flavors, extracts in the field of organic chemistry.

Wax, dyes, detergents, surfactants, pesticides, preservatives, synthetic resins, pigments, etc. in the field of inorganic chemistry.

Iron salts, ceramics, copier powders, magnetic materials, metal powders, photosensitive materials, various industrial chemicals, sample waste liquids, etc. in various automotive, marine propulsion fuel cell development fields.

Equipment Features

◆ Original imported nozzle for high efficiency.

◆ Color LCD touch screen displays parameters: incoming air temperature/outgoing air temperature/peristaltic pump speed/air volume/needle frequency.

◆ Fully automatic control: one-button startup, peristaltic pump starts automatically when temperature reaches preset level after setting spray process parameters, operation animation displayed on touch screen, clear display of operating process; machine automatically shuts down safely with a press of the stop button during shutdown.

◆ Manual control: easily switch to manual mode for adjusting process parameters during experiments, entire experiment process dynamically displayed on color touch screen (animation).

◆ Equipped with nozzle cleaner (needle probe) that automatically clears blockages and adjusts needle frequency as needed.

◆ Shutdown protection function: machine stops immediately upon pressing the stop button during shutdown, ensuring heating elements are not damaged due to operator error (forceful fan shutdown).

◆ Spray, drying, and collection systems made of transparent high-quality borosilicate heat-resistant glass for contamination-free drying process.

◆ Built-in imported oil-free air compressor with powder particle size distribution, excellent flowability, very low noise level (<60db).

◆ Two-fluid spray atomization structure, whole machine manufactured using high-quality stainless steel material, compact design without any additional equipment required.

◆ Real-time adjustable PID constant temperature control technology used for drying temperature control, ensuring accurate full temperature zone control with heating control accuracy of ±1℃.

◆ Equipped with inlet air filter to maintain sample purity.

◆ (For benzene, methanol, ethanol, etc., optional nitrogen gas device for added safety)

◆ Feeding amount adjustable via feeding peristaltic pump, minimum sample volume of 50ml.

◆ Powdered product after drying has uniform particle size, with over 98% of powder falling within same particle size range.

◆ For sticky materials, nozzle cleaner (needle probe) automatically clears blockages and adjusts needle frequency as needed.

◆ Innovative tower wall blowing device for higher material recovery rate.

◆ Unique protection functions: fan cannot start, heater cannot start, fan airflow can be adjusted.

Technical Parameters

|

Quality Standards |

Export Standard |

|

Incoming Air Temperature Control |

30°C to 300°C |

|

Outgoing Air Temperature Control |

30°C to 140°C |

|

Evaporation Water Volume |

200mL/h to 2000mL/h |

|

Maximum Feeding Amount |

Up to 2000mL/h (adjustable) |

|

Feeding Method |

Adjustable peristaltic pump, feeding amount: 30-2000mL/h |

|

Minimum Feeding Amount |

50mL |

|

Temperature Control Accuracy |

±1°C, using imported temperature control system |

|

Average Drying Time |

1.0 to 1.5 seconds |

|

Drying Air Flow Rate |

Air volume 0-330m3/h, air pressure 686Pa |

|

Compressor |

Imported oil-free air compressor with excellent flowability and very low noise level |

|

Nozzle (needle probe) |

Needle frequency can be adjusted (built-in 2.3bar compressed air supply) |

|

Nozzle Diameter |

0.5mm/0.7mm/0.75mm/1.0mm/1.5mm/2.0mm optional, |

|

Shutdown Protection Function |

During shutdown, simply press the stop button, |

|

Total Power of the Machine |

3.5KW / 220V |

|

Overall Dimensions |

1250mm (Height) x 650mm (Length) x 800mm (Width) |

Random Components

|

Serial Number |

Name |

Quantity |

|

1 |

Glass drying chamber |

1 |

|

2 |

Glass cyclone separator |

1 |

|

3 |

Glass sample collection bottle |

2 |

|

4 |

Glass sample collection tube |

1 |

|

5 |

Feed silicone tube 6mm |

2m |

|

6 |

Spray chamber |

1 |

|

7 |

Clamp (LY12 black) |

4 |

.png?x-oss-process=image/resize)