SYH Series 3D Motion Mixer

SYH series three-dimensional motion mixer has multi-directional movement of the mixing barrel, so that the material in the barrel crosses the mixing point more, the mixing effect is high, the uniformity can reach over 99.9%, and the maximum loading factor can reach 0.9 (normal mixing The machine is 0.4 to 0.6), the mixing time is short and the efficiency is high. The machine's mixing bucket body design is unique, the inner wall of the barrel is finely polished, no dead angle, no contaminated material, convenient discharge, cleaning...

Performance Characteristics

The loaded cylinder is driven by the driving shaft to perform the compound movements such as translation, rotation and rolling, which cause the material to move along the cylinder in three directions, thereby realizing the mutual flow and diffusion of multiple materials. Accumulation and doping. To achieve the purpose of uniform mixing.

Adapt To The Material

◎ This machine mixing bowl moves in many directions, the material has no centrifugal force, no gravity segregation and delamination, accumulation phenomenon, each component can have a large weight ratio, high mixing rate, is an ideal product in a variety of current mixers .

◎The loading rate of the cylinder is large, up to 90% (only 50% for ordinary mixers), high efficiency and short mixing time.

◎ The barrel is full of circular transitions and is precision polished.

◎ It is used for high uniformity mixing of powdery and granular materials used in pharmaceuticals, chemicals, food, light industry, electronics, machinery, mining and metallurgy, national defense industry, and various research institutes.

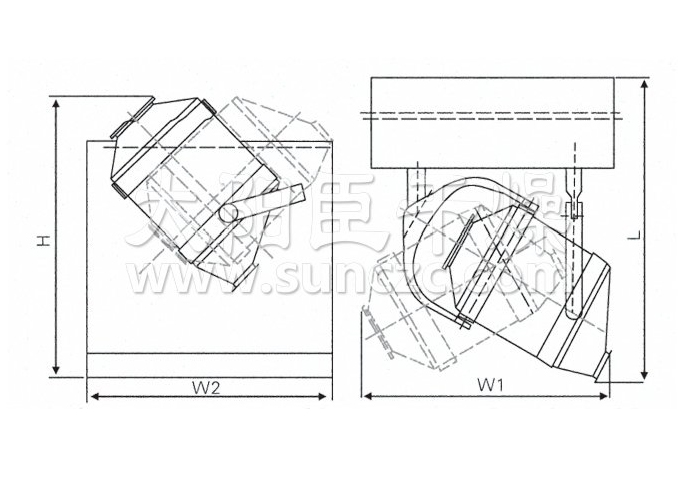

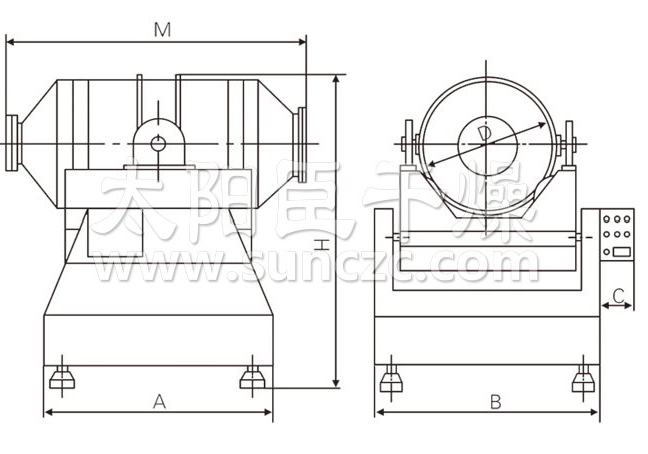

Schematic

Technical Specifications

| model | SYH-5 | SYH-15 | SYH-50 | SYH-100 | SYH-200 | SYH-400 | SYH-600 | SYH-800 | SYH-1000 | SYH-1200 | SYH-1500 | SYH-2000 |

| Barrel volume (L) | 5 | 15 | 50 | 100 | 200 | 400 | 600 | 800 | 1,000 | 1200 | 1500 | 2000 |

| Maximum loading volume (L) | 4.5 | 13.5 | 45 | 90 | 180 | 360 | 540 | 720 | 900 | 1080 | 1350 | 1800 |

| Maximum loading weight (kg) | 1.5-2.7 | 4-8.1 | 15-27 | 30-54 | 50-108 | 100-216 | 150-324 | 200-432 | 250-540 | 300-648 | 400-810 | 500-1080 |

| Spindle speed (r/min) | 0-20 | 0-20 | 0-20 | 0-20 | 0-15 | 0-15 | 0-13 | 0-10 | 0-10 | 0-9 | 0-9 | 0-8 |

| Motor power (kw) | 0.25 | 0.37 | 1.1 | 1.5 | 2.5 | 4 | 5.5 | 7.5 | 11 | 11 | 15 | 18.5 |

| Size (mm) | 600×1000 × 1000 |

800 × 1200 × 1000 |

1150 × 1400 × 1000 |

1250 × 1800 × 1550 |

1450 ×2000 ×1550 |

1650 ×2200 ×1550 |

1850 ×2500 ×1750 |

2100 × 2650 × 2000 |

2150 × 2800 × 2100 |

2000 × 3000 × 2260 |

2300 ×3200 ×2500 |

2500 × 3500 × 2800 |

| Weight (kg) | 100 | 200 | 300 | 800 | 1200 | 1200 | 1500 | 1700 | 1800 | 2000 | 2400 | 3000 |

NOTE: Material Press bulk specific gravity 0.6 g of / cm & lt . 3 is a meter, such as beyond, indicate when ordering.